Is Your Fresh Food Kitchen Ready to Scale?

Replication challenges could stunt your growth.

"Embracing Al and lot in our operations and supply chain allows us to have unprecedented control and agility. This transformation is not just about efficiency but also about ensuring we can sustainably meet the growing demands of our consumers."

Production

Scaling Blocks in Your Kitchen

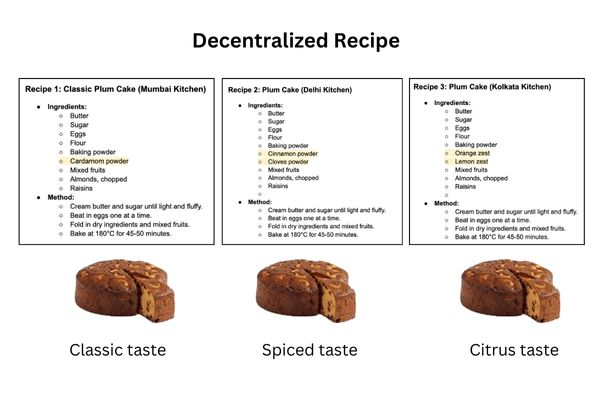

Decentralized Recipe Management

Product quality varies due to different recipe interpretations, and scaling is hard because control is spread out.

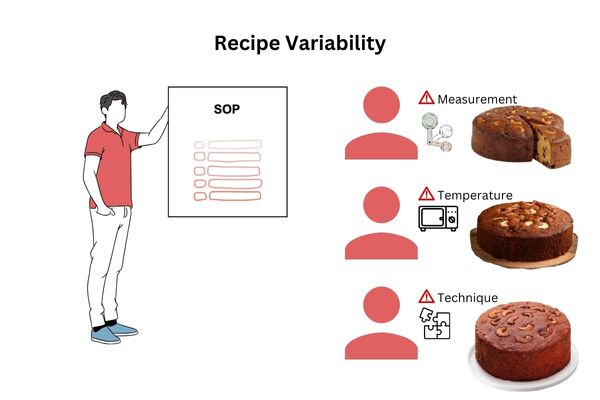

Recipe Variability

Inconsistent recipes hinder standardization, making it difficult to replicate processes across multiple production lines or locations, limiting growth.

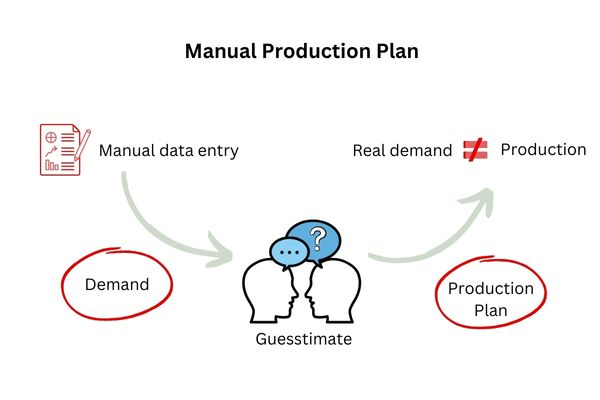

Production Planning Inefficiencies

Poor planning leads to unpredictable production cycles, making it challenging to increase output without significant resource overallocation, thus limiting scalability.

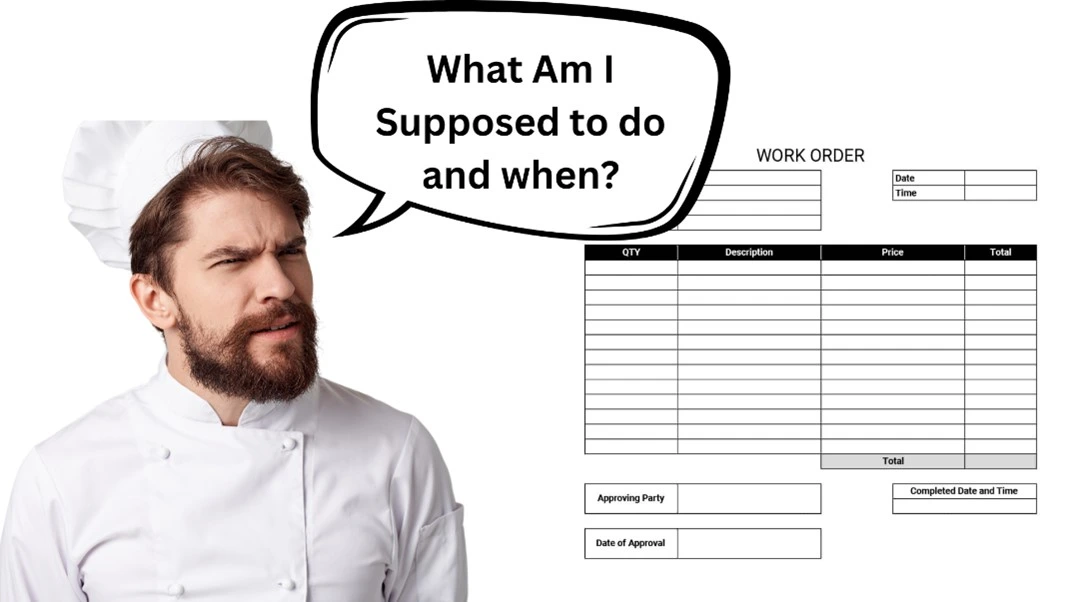

Scheduling Work Orders

Inefficient workforce utilization prevents optimal resource allocation, hindering the ability to increase production capacity.

FIFO Mismanagement

Food waste and safety risks due to improper FIFO can disrupt production flow, limiting the ability to increase output without compromising quality or safety.

Manual Labelling

Inadequate traceability makes it difficult to track and manage inventory efficiently, hindering the ability to scale production without risking product quality.

Manual Training

Slow onboarding and skill gaps limit the speed at which new employees can become productive, hindering the ability to rapidly increase production capacity.

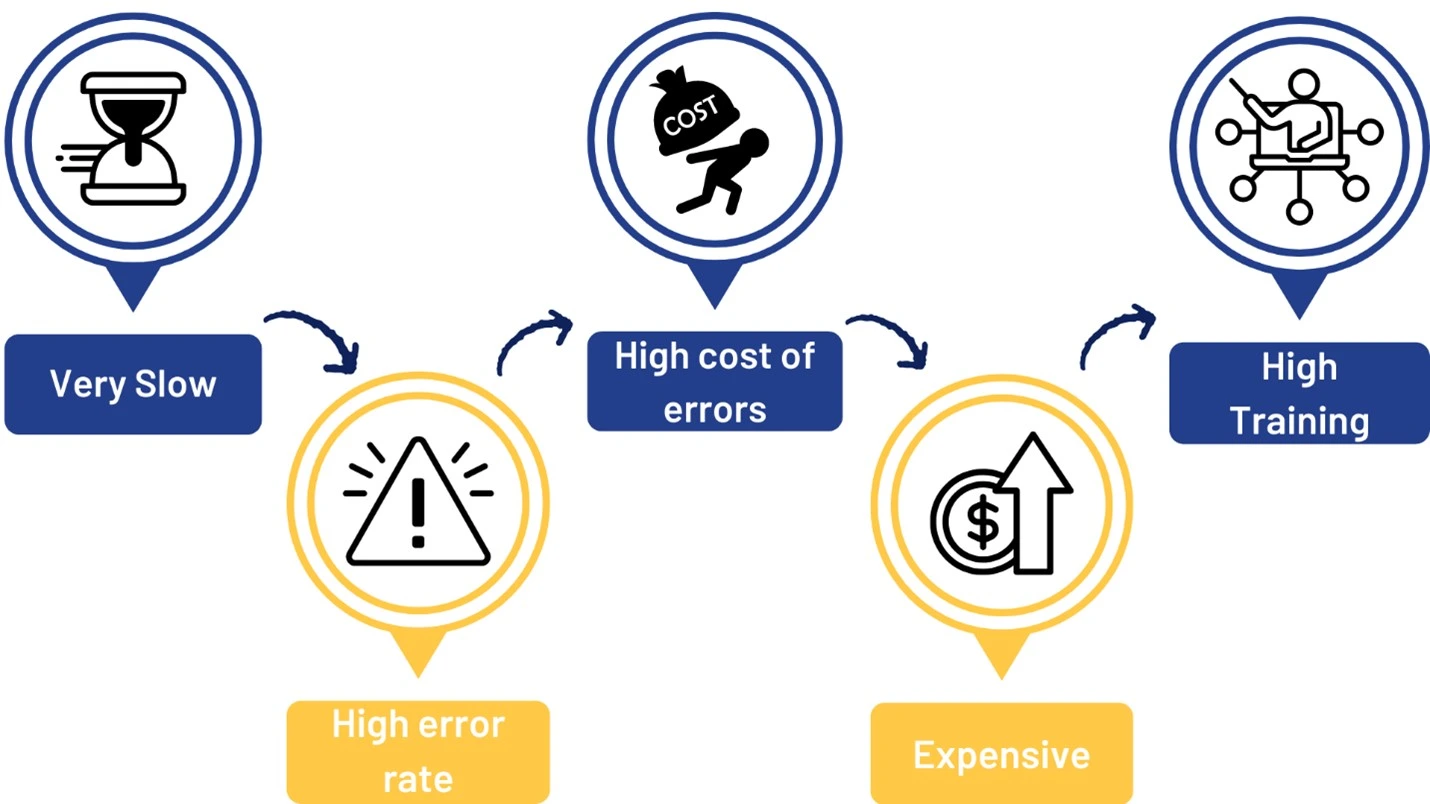

Process Inefficiencies

Inefficient processes increase production time and cost, making it difficult to achieve economies of scale.

Skill Replication Challenge

Slow knowledge transfer prevents rapid skill development, and high chance of human errors, limiting the ability to expand the workforce and increase production.

Unreliable Day-end Audits

Inaccurate data hinders effective decision-making, making it challenging to identify areas for improvement and optimize operations for growth.

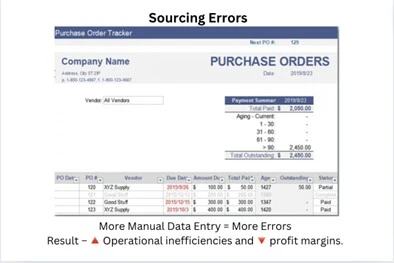

Sourcing

Manual sourcing limits business growthManual processes slow down suppliermanagement and order tracking, hinderingscaling efforts as demand increases

Troubling Inefficient Supply Chain

![]() Delayed & Unreliable Shipments → Cause network-wide operational standstills.

Delayed & Unreliable Shipments → Cause network-wide operational standstills.

![]() Supplier Complexity → Leads to unsustainable cost structures.

Supplier Complexity → Leads to unsustainable cost structures.

![]() Ingredient Variability → Results in menu inconsistencies across locations.

Ingredient Variability → Results in menu inconsistencies across locations.

Warehousing

Traditional warehousing blocks expansionManual inventory management leads tostock issues and mismanagement,restricting scalability

The Silent Chaos in Your Warehouse

![]() Inconsistent Inventory Systems → Impede multi-location management.

Inconsistent Inventory Systems → Impede multi-location management.

![]() Manual & Unstandardized Processes → Limit scalability and onboarding speed.

Manual & Unstandardized Processes → Limit scalability and onboarding speed.

![]() Inefficient Space Utilization → Constrains inventory growth and training.

Inefficient Space Utilization → Constrains inventory growth and training.

Distribution

Manual distribution struggles with higher volumesManual dispatch processes lead to delays, errors, and higher costs, limiting the business's ability to scale efficiently

Distribution Barriers Blocking Your Expansion

As you expand, the inability to efficiently track and verify internal movements becomes a critical bottleneck.

![]() Manual Processes → Slow down new outlet integration and admin efficiency.

Manual Processes → Slow down new outlet integration and admin efficiency.

![]() Inconsistent Temperature Tracking → Restricts geographical expansion.

Inconsistent Temperature Tracking → Restricts geographical expansion.

![]() Fragmented Delivery Data → Hinders efficient resource allocation.

Fragmented Delivery Data → Hinders efficient resource allocation.

Outlet

Disconnected oulet operations hinder multi-outlet expansionDisparate data systems across outlets lead to operational confusion and inconsistent customer experiences, hampering growth.

Storefront Pitfalls Impeding Expansion

![]() Inconsistent Stock Rotation → Slows uniform implementation and expansion.

Inconsistent Stock Rotation → Slows uniform implementation and expansion.

![]() Delayed Performance Metrics → Hinders quick decision-making.

Delayed Performance Metrics → Hinders quick decision-making.

![]() Fragmented Checkout Systems → Complicate rapid deployment of new stores.

Fragmented Checkout Systems → Complicate rapid deployment of new stores.

Unleash Your Food Business's Full Potential

The challenges you face are just the beginning. Behind the scenes, inefficiencies are silently sabotaging your growth. UY offers targeted tech solutions to transform these obstacles into opportunities. Don't let outdated systems hold you back.